Prototyping plays a really important role in the manufacturing process. Regardless of the industry, using the right prototyping procedure can help to ensure even some of the smaller, more complex parts provide an efficient solution during the manufacturing operations. There are different options available when it comes to prototyping. In this post, we compare CNC machining vs. 3D printing and show you in which applications each option will be the suitable choice.

Understanding CNC Machining And 3D Printing

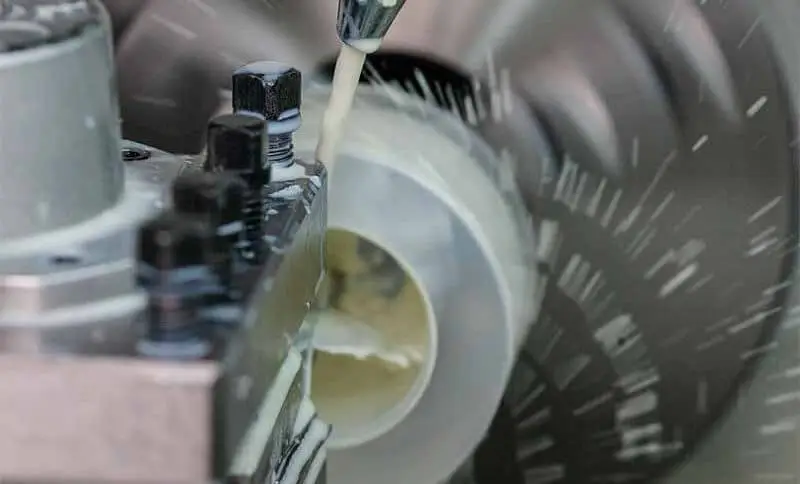

CNC machining, sometimes also referred to as CNC prototyping, is a term that uses a computer numerical control system in order to manufacture certain parts that can be used during the assembly or production of larger systems. It is a subtractive type of manufacturing process that starts with a blank. This blank is the foundation of the prototype, and material layers are then removed from the block in order to produce the final prototype.

3D printing, on the other hand, uses filaments loaded into a special machine in order to “print” a specific part. The part is first modeled through computer software and then loaded onto the machine for printing.

Differences Between CNC Machining And 3D Printing

There are differences between these two processes that can be used in prototyping. When you have a greater understanding of the differences that exist in a comparison between CNC machining vs. 3D printing, then it’s much easier to determine which solution is right for your needs.

- Applications: CNC machining is a good solution for accurate production. With 3D printing, mass customization can create an entire finished product as well as separate parts.

- Materials:Both of these technologies can be used with plastics, metals, and polymers, but some may find that CNC can use diverse materials, including metal alloys, wood, acrylics, modeling foam, and thermoplastics.

- Waste:When comparing CNC machining vs. 3D printing, CNC options generally tend to have a larger amount of waste. This is due to the use of a starting blank block and the removal of layers.

- Operating Costs:3D printing presents a more cost-effective solution for prototyping at a smaller scale compared to CNC machining.

- Use of Tools:Filament and a compatible printer are the major tools used in 3D printing. CNC machining may require more tools depending on the specifics of the item that you need to make.

- Precision:In a comparison of CNC machining vs. 3D printing, CNC machining can produce components with extremely high precision and accuracy because CNC machines are programmed with specific instructions and follow them strictly.

- Post-Processing:CNC machining can produce high-strength components in undisrupted native materials, while it can be challenging for 3D printing.

When To Use CNC Machining Vs. 3D Printing

Now that you have a better idea about CNC machining vs. 3D printing, it’s time to consider when you should use each.

If you are looking to prototype a part quickly or want to create the complete finished product without the need to assemble things first, then 3D printing might be the solution you are looking for. On the other hand, for large-scale projects where you need highly-precise parts that will be used during assembly, CNC machining could be the better choice.

CNC Prototyping From Hua-Pin

While many companies can offer you access to prototyping services, some set the bar above the rest. This is where Hua-Pin comes into the picture. As a prototyping specialist, we at Hua-Pin understand the need for a reliable partner when comparing CNC machining vs. 3D printing.

Our experts have accumulated years of experience in the CNC prototyping market, which ensures we can deliver customized and flexible solutions that help to streamline your manufacturing operations. At Hua-Pin, we offer a wide range of CNC machining material options, including metals and plastics, along with a versatile collection of finishes that you can explore for your project.

Conclusion

Hua-Pin has been offering a versatile range of prototyping services that meet the specific requirements of every client’s project. We specialize in delivering rapid prototyping manufacturing, ensuring your projects can get to market faster and with fewer errors in the way. Reach out to learn how we can help your manufacturing process become simpler and more efficient.