In the manufacturing industry, businesses need quick solutions, especially when developing a prototype. Speed, however, is not the only thing that needs to be taken into consideration. When working with prototypes, quality and the use of the right materials should also be priorities. A 3D prototype using specialized printing hardware can be an excellent choice here. Let’s look at how the process works and what it can do for manufacturers.

What Is 3D Printing, And How Does The Process Work?

When it comes to using printing solutions for 3D rapid prototyping, it is important to understand how the process works. There are three steps involved, each playing a particularly important role:

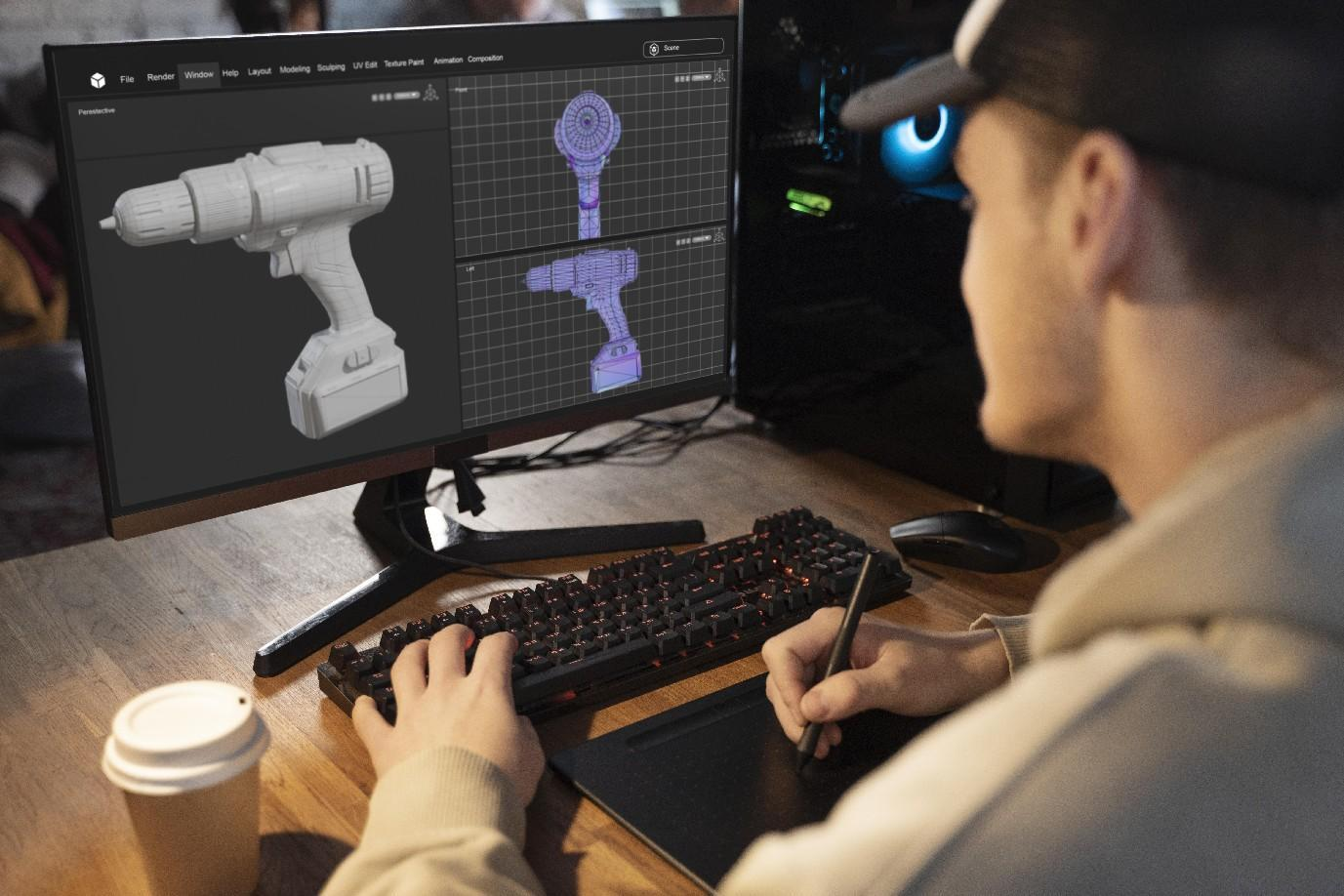

- Modeling: The first step involves digital processing, where digital prototypingis used to create a virtual model of the 3D prototype that the manufacturer requires. Expertise is required to ensure accurate modeling and the use of appropriate solutions.

- Slice:The slicing process helps to provide finishing touches to the 3D prototype after it has been modeled in the previous step. This helps to ensure there are no unwanted elements that will be printed in the final step of the process.

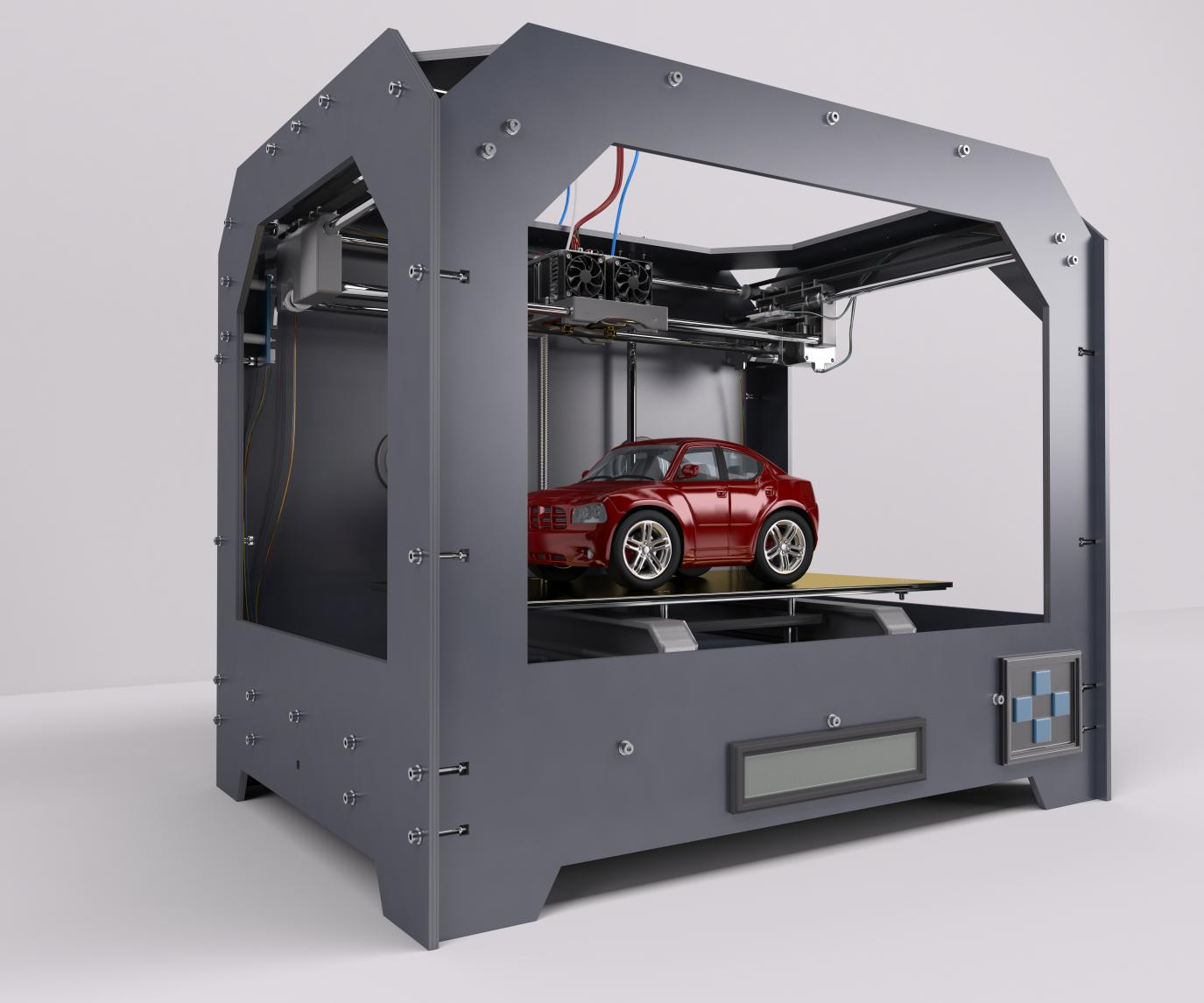

- 3D Printing & Post-Processing: The third step is to actually print the model into a real-world object. Various materials can be used at this point to ensure the prototype offers a high-quality solution that can be tested in the actual manufacturing process. In some cases, post-processing may be done in order to ensure the prototype is in line with the requirements of the manufacturer.

The Benefits of Using 3D Printing For Manufacturing

The use of 3D rapid prototyping in the manufacturing process can provide a number of potential benefits. Apart from understanding how the process works, manufacturers should also take a closer look at the benefits that it can offer them.

- The use of a 3D prototype presents a cost-effective strategy when it comes to manufacturing a small batch ofparts, especially when complex shapes are involved.

- The process is also much faster and minimizes material waste compared to some of the more traditional options that manufacturers have relied on for many years.

- It’s possible to use a single platform to build parts that are identical to each other, with minimal risk of structural differences due to the use of 3D printing technologies.

Applications For Industrial 3D Printing

Industrial 3D prototype solutions can be used in a number of different scenarios.

- Mechanical Engineering:In mechanical engineering, 3D printing can be used to create even some of the smallest parts that are required in the assembly process.

- Automotive:Various complex parts elements of vehicles, including body panels, chassis, seat belt guide, and structural parts, can be prototyped and produced with the use of 3D printing services.

- Tool-making:It is also possible to utilize 3D printing with metal materials in order to create high-quality tools such as work holding, cutting tools, and foundry water jacket mold cores for various purposes.

- Medical Devices and Dentistry:In certain cases, 3D printing is also used in order to assist in the production of medical devices, from 3D-printed prosthetics to joint replacements. A 3D model is also can be used for dental correction, implants, or veneers.

- Aerospace:Due to the high-quality results that can be obtained through 3D printing, the aerospace industry can also benefit from using 3D prototypes to produce jigs, fixtures, surrogates, and metal brackets.

Hua-Pin: Reliable Industrial 3D Printing Services

Various solutions and vendors are available for manufacturers who require a 3D prototype solution, but the overall service level can differ among these providers. Hua-Pin has been providing 3D printing services and prototyping solutions for several years and continues to ensure they use the latest innovations for clients.

Hua-Pin focuses on helping manufacturers save money during prototyping and to offer a complete bridging solution for the production process. We specialize in a diverse selection of 3D prototyping solutions and are ISO9001-2015 certified. Hua-Pin serves as a reliable partner throughout the prototyping and manufacturing process.

Conclusion

Hua-Pin offers a diverse selection of rapid prototyping services, including 3D printing. We work closely with our clients to help bring solutions to the market in less time while also ensuring their flexible selection of prototyping services. For more details on how HUAPIN can offer a 3D prototype solution, get in touch with us.