Rapid prototyping plays a pivotal role in product design by enabling swift, effective physical modeling of conceptual designs. It accelerates the evaluation of form, function, and user experiences for designers, engineers, and companies alike. By leveraging additive techniques, rapid prototyping manufacturing streamlines development timelines and cuts costs relative to conventional manufacturing workflows. These advantages have established it as an essential part of bringing innovations to life across industries.

Rapid Prototyping Manufacturing: Popularity in the Development Process

Rapid prototyping is very popular in the development process, and it’s not surprising considering its many unique advantages. Key reasons for increased popularity include:

Reduce the Enterprise’s Design-to-Production Timeline from Months to Weeks

Fabricating initial prototypes and making revisions becomes quicker and far more efficient for businesses with rapid prototyping manufacturing than with traditional prototyping methods.

Be Ideal for Testing New Materials and Component Geometries

Rapid prototyping allows experimenting with various innovative materials and complex geometric designs that would otherwise be impossible or too expensive using conventional techniques.

Improve User Involvement During the Design Stages of NPD

Engineers can get early user and customer feedback on form, fit, and function through rapid prototyping physical mockups and models.

Be Able to Evaluate Human Factors and Ergonomics

Rapid prototyping manufacturing allows the rapid creation of models for the evaluation of human-product interactions to ensure safety, comfort, and usability before finalizing the design.

Reduce Overall Product Development Cost

Rapid prototyping streamlines the product development process and compresses timelines substantially, hence bringing the product to market faster at much lower costs than traditional methods.

Types and Applications

Rapid prototyping has four main types. Each type has specific applications that make it suitable for certain prototyping needs. Depending on the prototyping requirement, such as form, fit, function, or material evaluation, a specific rapid prototyping manufacturing type may be best suited to efficiently advance the product development cycle at low costs.

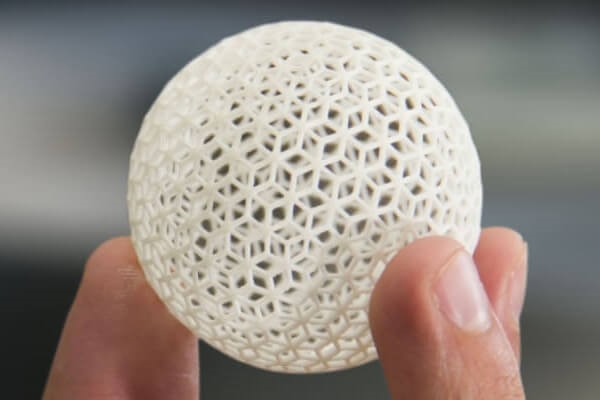

3D Printing

3D printing includes additive manufacturing techniques that create 3D objects layer by layer under computer guidance. Popular rapid prototyping methods of 3D printing deliver visual models, enable wear/fit evaluation, and produce proof of concept prototypes, amongst other applications. Its versatility has seen utilization span areas like electronics design validation.

CNC Prototyping

CNC prototyping utilizes computer-controlled machine tools to cut various materials precisely. It is used for functional prototypes, design validation, and form and fit assessments. CNC machining can create tightly tolerant parts and complex geometries in aluminum, steel, and other metals that are ideal for testing functional aspects.

Urethane Casting

Urethane casting makes silicone molds via the prototype as a pattern, then pours liquid urethane resin into the mold and lets it cure. It leads to prototypes that use realistic textures and colors to mimic the look and feel of final production parts. Urethane casting works well for flexible parts, medical models, and rapid prototyping manufacturing that involves complex geometries and surface details.

Sheet Metal Prototyping

Sheet Metal Prototyping uses machine tools and bending processes to form enclosures, housings, and other flat or folded sheet metal components that are typically found in electronics and appliances. It is a cost-effective option to produce and test form, fit, and functional aspects involving metal casings and chassis before production.

HPrapid Delivers Dependable Rapid Prototyping Service

It is important to choose a reliable rapid prototyping service provider for high-quality outputs on time. HPrapid is a leading brand in this domain with over a decade of experience and expertise. As a certified company, we are committed to excellence, efficiency, and affordability in prototyping and low-volume manufacturing.

We provide a comprehensive rapid prototyping manufacturing service. We use advanced 3D printing, CNC machining, injection molding, and other methods to achieve quality results. Our experienced team utilizes various additive and subtractive processes to produce complex parts directly from 3D CAD data, hence ensuring precision, repeatability, and quality standards with advanced equipment and quality control procedures. Furthermore, we also offer flexible design iterations and material options to effectively evaluate form, function, and production feasibility.

Conclusion

At HPrapid, we reduce costs and lead times through streamlined and comprehensive prototyping solutions compared to traditional methods. We also provide full project management and after-sales support from concept design to final prototype delivery. You can contact us to learn more about our services and the company in general.