Outsourcing rapid prototyping to China is very popular nowadays. This article aims to give you an idea about outsourcing your projects here if you are planning on doing it for the first time.

History of rapid prototyping in China

Before we go ahead with the discussion, I would like to introduce a brief history of Chinese rapid prototyping to provide some basic knowledge.

- 30 years ago. According to information I have received from veterans in the industry, China began prototyping in significant numbers around 30 years ago. Of course, I am not talking about 3D printing or CNC machining: every prototype during this time period was made manually. That’s why we translate prototype to “shou ban,” which means “handmade samples.”

- 20 years ago. Go back 20 years, and Hong Kong and Taiwan-based prototyping companies began to carry out their work (including moldmaking) using 3D printers and CNC machines. The price to make a prototype, however, was sky high.

- 15 years ago. Around 15 years ago, lots of Chinese prototyping businesses started to spring up with locally made CNC machines in their factories. I have personally been part of this industry for around 15 years, and I have seen what has happened over this timespan.

- 7 years ago. Less than a decade ago, Chinese rapid prototyping companies started to invest in high-quality plastic and metal 3D printing machines, as well as high-precision CNC machines, including 5-axis machines. Companies like us.

- Now. Today, rapid prototyping is highly developed in China, and you can outsource the manufacture of almost any type of prototype part here.

Advantages of Chinese rapid prototyping

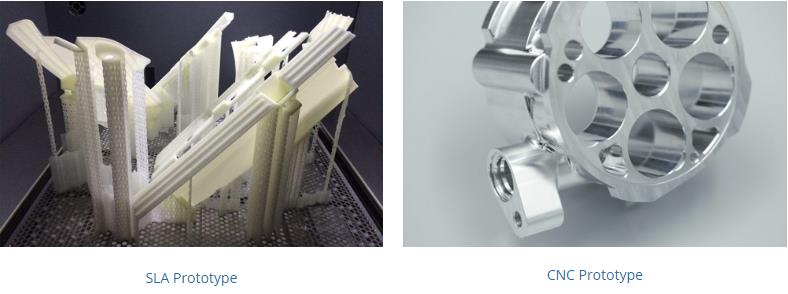

- Compared with Western prototyping companies, there is still quite a distance for Chinese prototyping companies to catch up. If you need super-precise prototypes, let’s say something with a tolerance of +/- 0.005 mm, it is probably not a good idea to buy it here.There are some companies with high-end machines that can achieve this type of tolerance, for sure, but they are not in the prototyping business. Importantly though, most prototypes require only a reasonable tolerance. So over 95% of prototypes are suitable for Chinese prototyping companies.In the past, 3D printing prices were very high here, since the machines and material were imported — demanding high tax and delivery costs. What’s more, you couldn’t get much of a bargain by outsourcing here, since very little labor is involved in 3D printing. The price of CNC parts, however, was generally very competitive, since Chinese companies could offer low machining labor costs.Now things are changing again: due to increasing labor costs, the price of CNC machined parts is gradually increasing. But with locally made SLA 3D printers and materials, the price of a printed SLA prototype today is about 1/10 of what it used to be. I am confident the price of SLS, SLM & DMLS prototypes will drop in the future as well.

- Compared with other Asian prototyping companies, things are a little different. Aside from Japan and South Korea, most Asian countries have lower labor costs than China.That being said, making quality prototypes isn’t just about setting up a good company. The supply chain is also very important: without quality materials and surface finishing options, for example, a prototype will be substandard. Experience is also a key issue: lots of Chinese companies have tried to expand to countries like Vietnam and Burma, but no prototyping company has been able to successfully transfer its production to those places due to supply chain issues and a lack of local experience.

How to identify a good Chinese rapid prototyping company

There are thousands of rapid prototyping companies in China. But from what I can see, lots of these companies (at least 70%) are not truly ready for the overseas market — either in terms of quality or range of services. That’s why people sometimes have a negative picture of Chinese manufacturing.

The problem is that when you search “rapid prototyping in China,” you get dozens of results. So how can you tell which ones are good and which are not? One important thing to remember is that appearances can be deceiving.

Sometimes a company’s website looks like this:

When the company itself is more like this:

This is not a joke! Our website has been copied by other local prototyping companies. Once we even received a marketing email with our own pictures from our website. In other words, you have to look further than a company’s home page.

Here are some suggestions if this is your first time outsourcing prototypes from China.

- Visit the companies. The best way to assess a company is, of course, to visit it. If you have time and resources to do so, you can gain a clear idea about what kind of facilities the company has in house, how many people work there, what kind of work procedures they use, etc. For example, you’ll be able to find out: Does the company check the parts during manufacturing? Does it inspect parts properly before shipping?

- Ask lots of questions. Asking as many questions as possible — especially technical questions — is another way to verify a company. If the salesperson knows all the technical points and knows exactly what you want and what you need, then you can be fairly confident about them doing a good job for you. If they stumble over your questions, you should step away without hesitation. Because if the sales contact doesn’t know what you want, the machinist definitely won’t.

- Check if they are certificated company. ISO certifications and other credentials do not necessarily mean that a company is reliable, but they do at least show that the company is audited by the third party that will follow up on procedures.

- Get a reference. If someone you know has experience outsourcing from China, ask them about their experiences. They may be able to tell you which prototyping companies are good (or otherwise!) based on their previous orders.

How to make your final decision after gathering quotes from a shortlist of companies

For any given project, you should try to get quotations from a handful of promising-looking companies. Once you have done that, consider the following factors before making your final decision.

- Price. The cost of a project is, of course, one of the most important factors when choosing a prototyping supplier. Some companies may quote very high prices if they think the customer has a very high budget. On the other hand, some companies may quote a very low price to secure the project.In my opinion, it pays to familiarize yourself with the actual material and labor costs of a project, so you can identify a fair and reasonable price. Super low prices may be attractive, but companies quoting these prices will realize they are going to lose money, then attempt everything in their power to cut their own expenditure. When this happens, the quality of the prototype will undoubtedly drop.

- Reliability. When we started up, we were a trading company without our own factory, so we had to outsource everything. During this period, we came across many “yes men”: manufacturers who would say yes to all technical points — regardless of their actual manufacturing capabilities. In the end, the difficult technical features would be done badly or omitted altogether.Conversely, some companies would say no to everything just to avoid risk, forcing the customer into a corner. In these cases, you would have to compromise on the goals of your project, even though your original plans were feasible. Being honest with our customers results in a better outcome for everyone.

Other things to consider

- Confidentiality. Some manufacturers are happy to show off a customer’s parts — during manufacturing or when finished — via social media. But these images and videos should never be made public. The first thing you should do with a prototyping partner is sign a non-disclosure agreement (NDA) with them.

- Shipment. Shipping overseas from China normally takes around 2 days — but sometimes longer. So for time-sensitive projects, you might consider a local prototyping partner for maximum efficiency. That being said, many Chinese prototyping companies work though the night, so may still be able to match or even beat the shipping times of local companies. Regarding weight and volume, large or heavy parts may result in high shipment costs — unless you are prepared to receive the parts via sea freight. For especially large or heavy orders, it might be more effective to stay local.

3ERP is one of the most reliable rapid prototyping companies in China. Click to hear what our customers say about us, or browse our rapid prototyping services if you want to know more about what we offer.