The material choice matters a lot in precision injection molding. This is because the properties of the molded part directly relate to the resin utilized. Applications with tight specifications necessitate a thorough evaluation of design, production feasibility, intended use conditions, and more to select a material meeting demands while withstanding processing. With many injection molding materials on the market, selection can prove difficult without guidance. This guide aims to provide insights into materials for molding and factors to examine to ensure the right selection for your application.

Common Types of Injection Molding Materials

Injection molding materials have many types that are commonly used for various applications/projects. The most common ones include:

- ABS

ABS (Acrylonitrile Butadiene Styrene) is an impact-resistant plastic that can be easily colored. It is commonly used to make toys and appliances.

- PP

PP (Polypropylene) is a lightweight, inexpensive material used for anything from automotive components to drinking bottles.

- PC

PC (Polycarbonate) is a clear, tough plastic with higher heat resistance than ABS. It is often used for lenses and medical or electronic applications.

- ASA

ASA (Acrylonitrile Styrene Acrylate) is similar to ABS but has better weatherability, making it suited to outdoor uses like trim.

- AES

AES (Acrylic Styrene Acrylonitrile) is an acrylic material that offers excellent clarity and is used for applications like lighting covers.

- PMMA

The lightweight material PMMA (Polymethyl Methacrylate) is known for its clarity and ability to be thermoformed. It is used in signs and glazing.

- PE

PE (Polyethylene) is inexpensive and can be either rigid or flexible. Common uses include containers, tubing, and automotive parts.

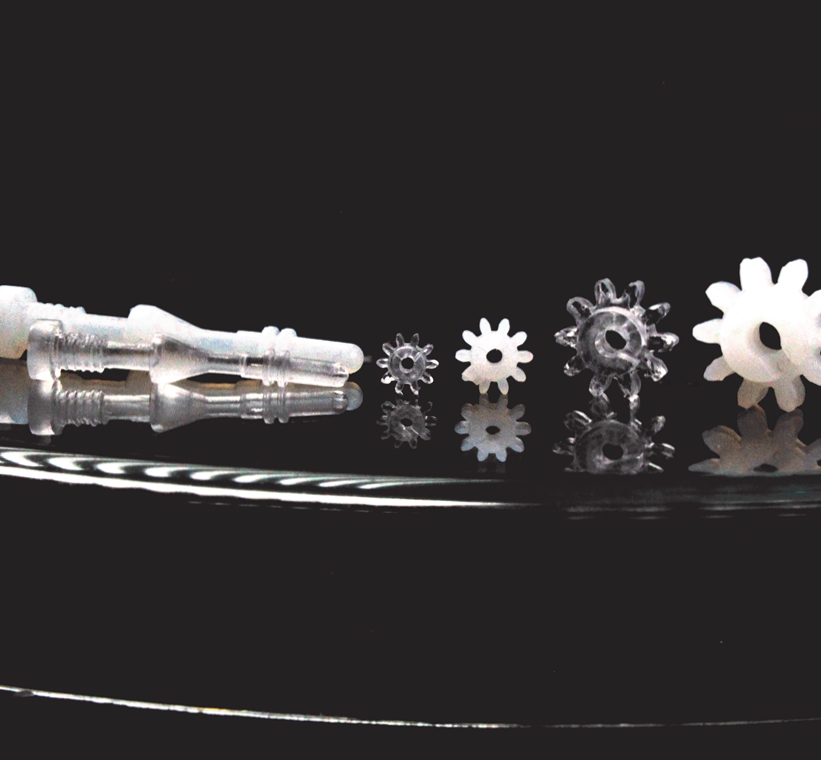

- POM

POM (Polyoxymethylene) has low friction and is self-lubricating. These characteristics make it suitable for applications like gears and slide plates.

- PA6

PA6 (Polyamide 6) is tough and abrasion-resistant. It also retains properties over a wide temperature range. These traits make it suitable for gears, pulleys, and brush bristles.

Key Factors in the Material Selection of Injection Molding

The following are some things you should consider when choosing injection molding materials for your specific application:

- Requirements and Specifications of the Desired Part

These play a crucial role in determining the suitable material. Evaluate characteristics like dimensions, tolerances, surface finish, flexural and tensile strength required, etc., based on the part’s intended functionality and the stresses it may experience.

- Mechanical Properties

Mechanical properties refer to how the material performs under force. Key considerations include the potential injection molding materials’ strength, stiffness, and impact resistance capabilities. These must be assessed for the part’s application and usage conditions based on expected load, stress, etc..

- Thermal Properties

Thermal properties deal with temperature performance. The molding process temperature limits and the part’s usage environment temperature ranges must be checked for compatibility with potential injection molding materials.

- Chemical Compatibility

The chemical compatibility analysis deals with how the material may interact with its usage environment. If the part is to be used in the presence of solvents, fuels, chemicals, etc., injection molding materials need to be evaluated for resistance to corrosion or deterioration from those substances.

- Cost, Availability, and Processing Characteristics

Along with technical feasibility, business and production practicality factors like material and mold costs, supplier dependability, molding process parameters, and part aesthetics influence the choice. Ease of processing and competitive pricing are important for commercial viability and market success.

HPrapid Offers Cost-Effective Plastic Injection Molding Service

HPrapid is a seasoned manufacturer committed to providing quality plastic prototyping and manufacturing solutions. Through our innovative techniques and approaches, we can have customer designs finished rapidly. This allows thorough testing and refinement of designs before mass production.

At HPrapid, we offer cost-effective plastic injection molding services for customers. Our advanced process is well-suited for mass manufacturing of plastic parts in a consistent quality across large volumes. As one of the premier injection molding companies, we can produce both prototypes and end-use production parts quickly (within just 15 days). We use aluminum molds that offer affordable tooling and fast manufacturing cycles. We also stock over 100 different thermoplastic resin materials for customers to select from.

Conclusion

Choosing the right injection molding material is crucial for precise, durable products. Considering mechanical, thermal, and chemical properties is key with various materials available. Balancing technical needs with cost and availability is vital. HPrapid offers a wide range of materials and expertise for cost-effective, high-quality injection molding, supporting innovation and success in manufacturing. Please contact us for a more extensive overview of our reliable plastic injection molding service and other solutions.